Testing

Testing

Rilon can test each and every product in four kind of phase. There are EMC Testing, SMIT Testing, ROHS Testing and Assembly Testing. So in this method maximum error products are filtered and defected products are again sent back to development phase. Shenzhen Riland products are always 100% defectless products.

EMC Testing

Electromagnetic compatibility is the ability of equipment or systems to function satisfactorily in their electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment. EMC testing is a series of tests to ensure the product’s electromagnetic compatibility. EMC compliance is a mandatory requirement in most markets including Europe, U.S., China, India, Korea, Australia and New Zealand. EMC testing is necessary to help you meet regulatory requirements, improve product performance and reduce the risk of costly non-compliance. Third-party EMC tests and conformity assessments also help to strengthen your competitive position in the market.

SMT Center

SMT is the ability of equipment or systems to function satisfactorily in their electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment. SMT testing is a series of tests to ensure the product’s electromagnetic compatibility. SMT compliance is a mandatory requirement in most markets including Europe, the U.S., China, Korea, Australia and New Zealand. SMT testing is necessary to help you meet regulatory requirements, improve product performance and reduce the risk of costly non-compliance. Third-party SMT tests and conformity assessments also help to strengthen your competitive position in the market.

ROHS Test

Shenzhen Riland Industry co., ltd, provides RoHS compliance product and material testing services through a global network of laboratories. Clients can identify their preferred test location and benefit from the ability to manage the project in real-time, while ensuring that costs are kept to a minimum. Testing can include standard testing for the EU RoHS Directive, China RoHS, Korea RoHS, and California RoHS requirements. Our RoHS analytical laboratories are staffed with expert chemists and advanced instrumentation for RoHS related electronic component testing.

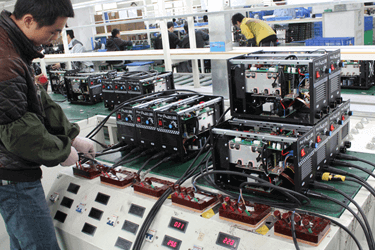

Assembly Test

Assembly testing moves one step ahead of Unit testing. It checks if two or more modules are able to communicate and produce expected results or not. No Unit in the system can perform stand alone activities. The output of one module may be used as input by another, so it is highly important if the related modules are able to connect and produce the desired result. Assembly testing is a way of Black box testing and can be done through the UI.

Assembly

Machine Assembly 1

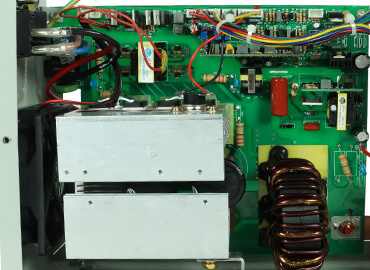

Machine Inner Parts 1

Rilon Warehouse

Inner Parts Fitting

Machine Outer Overview

Machine Inner Parts 2

Machine Part Testing 1

Machine Part Testing 2

Machine Part Testing 3

Machine Testing

Machine Development

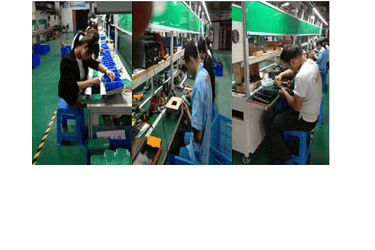

Overview of Assembling

Machine Testing

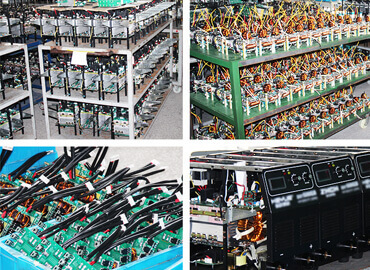

Board Assembly

Cirut Assembly

Chipset Assembly

Automatic Assembly

SMT Testing

Robot Site Commissioning

Robot Site Commissioning